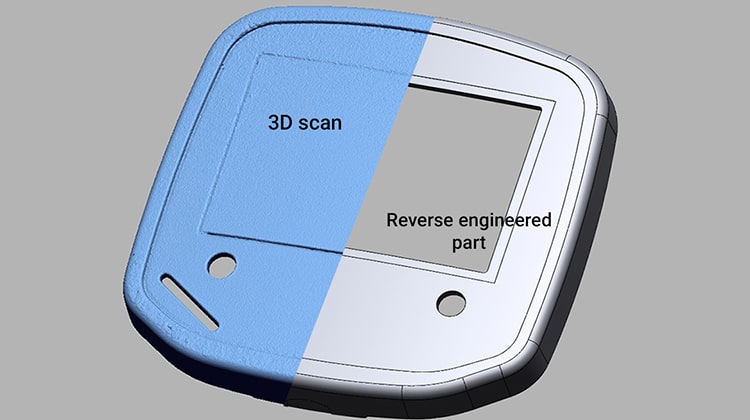

Project Overview: PeroWorx Engineering was engaged by a leading electronics manufacturer to reverse engineer a complex screen cover for one of their flagship products. The objective was to create an accurate 3D CAD model of the existing cover to facilitate manufacturing improvements and enable future design enhancements.

Challenges:

- Capturing the precise dimensions and intricate details of the screen cover, including mounting points and curvature.

- Ensuring the CAD model maintained exact tolerances to fit perfectly with other components of the device.

- Delivering the project within a tight timeline to meet the client’s production schedule.

Solutions:

- Utilized state-of-the-art 3D scanning technology to capture detailed measurements and features of the screen cover.

- Employed advanced CAD software to create a highly accurate 3D model, ensuring all critical aspects and dimensions were meticulously replicated.

- Conducted thorough validation and testing to verify the accuracy and compatibility of the CAD model with the original part.

- Collaborated closely with the client to incorporate any necessary modifications and ensure the final model met all specifications.

Outcome: The completed 3D CAD model of the screen cover exceeded the client’s expectations, providing a precise digital representation that enabled seamless integration into their manufacturing process. This allowed the client to enhance production efficiency and improve the overall quality of the product. The success of this project underscored PeroWorx Engineering’s capability in delivering high-precision reverse engineering solutions.

Client Feedback: “PeroWorx Engineering did an exceptional job with the reverse engineering of our screen cover. The accuracy and detail of the CAD model were impeccable, allowing us to make significant improvements in our manufacturing process. Their team was professional, responsive, and delivered on time. We highly recommend their services!”

Feel free to contact us with your needs.